The interface between the control computer and the servo motors is reasonably uncomplicated from an electronics point of view. A TTL/RS-232 line level converter (MAX-232) acts as the interface between the control computer and a Microchip PIC microcontroller. This microcontroller creates 10 unique square wave outputs. I'm not going to bore you with another description of those outputs unless the thousands of websites which already do such a good job all die. Examples are:

The interface between the control computer and the servo motors is reasonably uncomplicated from an electronics point of view. A TTL/RS-232 line level converter (MAX-232) acts as the interface between the control computer and a Microchip PIC microcontroller. This microcontroller creates 10 unique square wave outputs. I'm not going to bore you with another description of those outputs unless the thousands of websites which already do such a good job all die. Examples are: One note, though: many sites refer to this as "Pulse Width Modulation" and, I suppose this is correct as we are modulating the width of the pulse. That said, don't fall into the trap I fell into when starting out. The "value" of a PWM signal is often derived from the mark to space ratio. Don't assume that the servo position is a function of the mark to space ratio. It isn't. The servo position is derived purely from the width of the "high" pulse. At the same time, the entire duty cycle does need to be between 5 and 25ms.

One note, though: many sites refer to this as "Pulse Width Modulation" and, I suppose this is correct as we are modulating the width of the pulse. That said, don't fall into the trap I fell into when starting out. The "value" of a PWM signal is often derived from the mark to space ratio. Don't assume that the servo position is a function of the mark to space ratio. It isn't. The servo position is derived purely from the width of the "high" pulse. At the same time, the entire duty cycle does need to be between 5 and 25ms.

I noticed that standard Radio Control servos can easily draw 300mA at stall and a bit more when starting to move. This was causing my PIC to reset and my solution was to split the incoming battery power four ways through four 5V regulators. One regulator supplies the PIC and the serial interface and each of the other three supplies power to two or three of the servos.

That aside, my circuit has an LED. I like flashing lights.

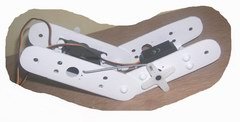

By the way, I made this PCB myself. I'll need to create a separate blog to show you how. Sure, it's been done before, too, but I really like my process.

No comments:

Post a Comment